Honda CR-V: Front Driveshaft Disassembly

Special Tools Required

- Threaded adapter, 26 x 1.5 mm 07XAC-001030A

- Slide hammer, 5/8"-18 UNF, commercially available

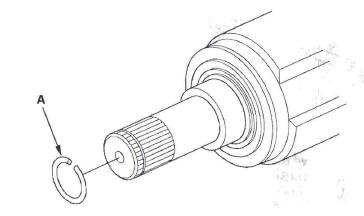

Inboard Joint Side

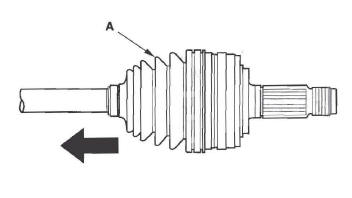

1. Remove the set ring (A) from the inboard joint.

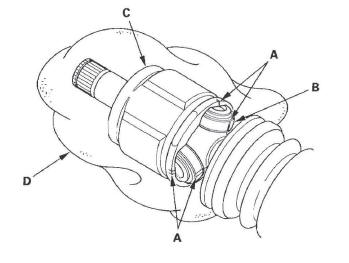

2. Remove the boot bands. Be careful not to damage the boot.

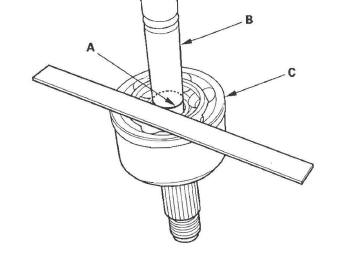

3. Make marks (A) on each roller (B) and inboard joint (C) to identify the locations of rollers and grooves in the inboard joint. Then remove the inboard joint on the a shop towel (D). Be careful not to drop the rollers when separating them from the inboard joint.

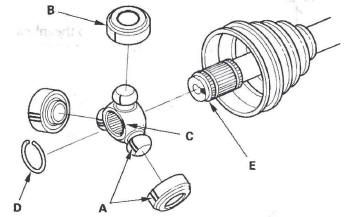

4. Make marks (A) on the rollers (B) and spider (C) to identify the locations of the rollers on the spider, then remove the rollers.

5. Remove the circlip (D).

6. Mark the spider and driveshaft (E) to identify the position of the spider on the shaft.

7. Remove the spider.

8. Wrap the splines on the drives haft with vinyl tape (A) to prevent damage to the boot.

9. Remove the inboard boot. Be careful not to damage the boot.

10. Remove the vinyl tape.

Outboard Joint Side

1. Remove the boot bands. Be careful not to damage the boot.

2. Slide the outboard boot (A) partially to the inboard joint side. Be careful not to damage the boot.

3. Wipe off the grease to expose the driveshaft and the outboard joint inner race.

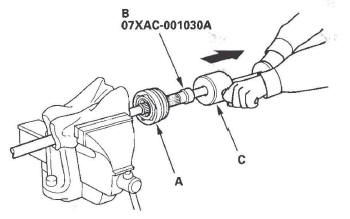

4. Make a mark (A) on the driveshaft (B) at the same level as the outboard joint rim (C).

5. Securely clamp the driveshaft in a bench vise with a shop towel.

6. Remove the outboard joint (A) using the threaded adapter (B) and a commercially available 5/8" - 18 UNF slide hammer (C).

7. Remove the driveshaft from the bench vise.

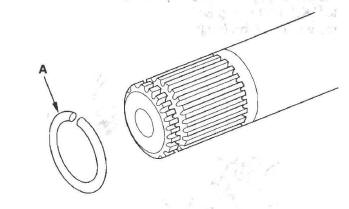

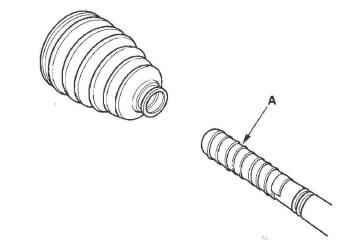

8. Remove the stop ring (A) from the drives haft.

9. Wrap the splines on the driveshaft with vinyl tape (A) to prevent damaging the boot.

10. Remove the outboard boot. Be careful not to damage the boot.

11. Remove the vinyl tape.