Honda CR-V: Crankshaft and Piston Removal

1. Remove the engine assembly.

2. Remove the transmission.

3. Remove the drive plate.

4. Remove the oil pan.

5. Remove the oil pump.

6. Remove the cylinder head.

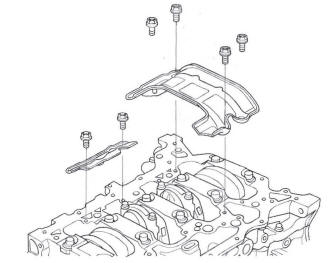

7. Remove the baffle plates.

8. Remove the 8 mm bolts.

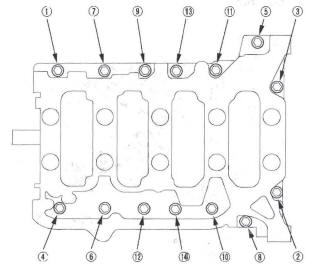

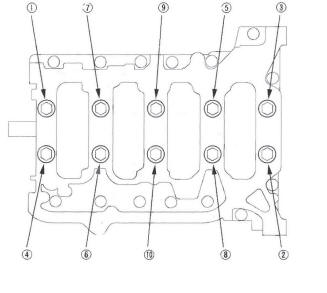

9. Remove the bearing cap bolts. To prevent warpage, unscrew the bolts in sequence 1/3 turn at a time; repeat the sequence until all bolts are loosened.

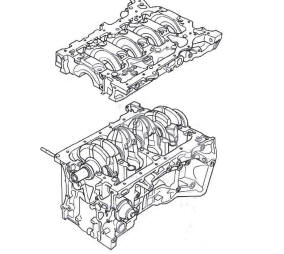

10. Remove the lower block and bearings. Keep all the bearings in order.

11. Remove the rod caps/bearings. Keep all caps/ bearings in order.

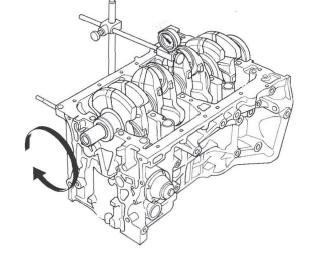

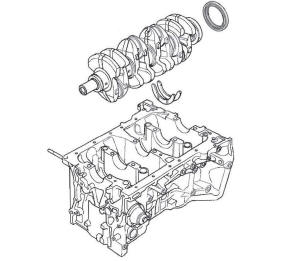

12. Lift the crankshaft out of the engine. Be careful not to damage the journals.

13. Remove the upper bearing halves from the connecting rods, and set them aside with their respective caps.

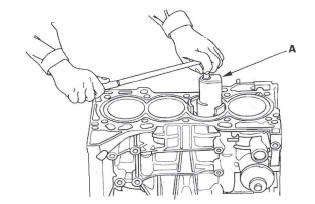

14. If you can feel a ridge of metal or hard carbon around the top of each cylinder, remove it with a ridge reamer (A). Follow the reamer manufacturer's instructions. If the ridge is not removed, it may damage the pistons as they are pushed out.

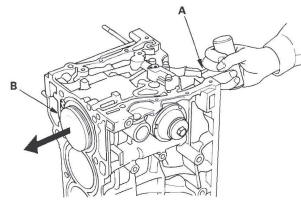

15. Use the wooden handle of a hammer (A) to drive out the piston/connecting rod assembly (B).

16. Reinstall the lower block and the bearings on the engine in the proper order.

17. Reinstall the connecting rod bearings and caps after removing each piston/connecting rod assembly.

18. Mark each piston/connecting rod assembly with its cylinder number to make sure they are reused in the original order.

NOTE: The existing number on the connecting rod does not indicate its position in the engine, it indicates the rod bore size.

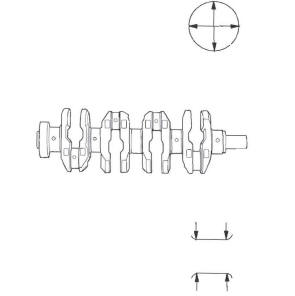

Crankshaft Inspection

Out-of-Round and Taper

1. Remove the crankshaft from the engine block.

2. Clean the crankshaft oil passages with pipe cleaners or a suitable brush.

3. Clean the keyway and threads.

4. Measure the out-of-round at the middle of each rod and main journal in two places. The difference between measurements on each journal must not be more than the service limit.

Journal Out-of-Round

Standard (New): 0.005 mm (0.0002 in.) max.

Service Limit: 0.010 mm (0.0004 in.)

5. Measure the taper at the edges of each rod and main journal. The difference between measurements on each journal must not be more than the service limit.

Journal Taper

Standard (New): 0.005 mm (0.0002 in.) max.

Service Limit: 0.010 mm (0.0004 in.)

Straightness

6. Place the engine block on the surface plate.

7. Clean and install the bearings on the No.1 and No. 5 journals of the engine block.

8. Lower the crankshaft into the block.

9. Measure runout on all main journals. Rotate the crankshaft two complete revolutions. The difference between measurements on each journal must not be more than the service limit.

Crankshaft Total Runout

Standard (New): 0.03 mm (0.0012 in.) max.

Service Limit: 0.04 mm (0.0016 in.)